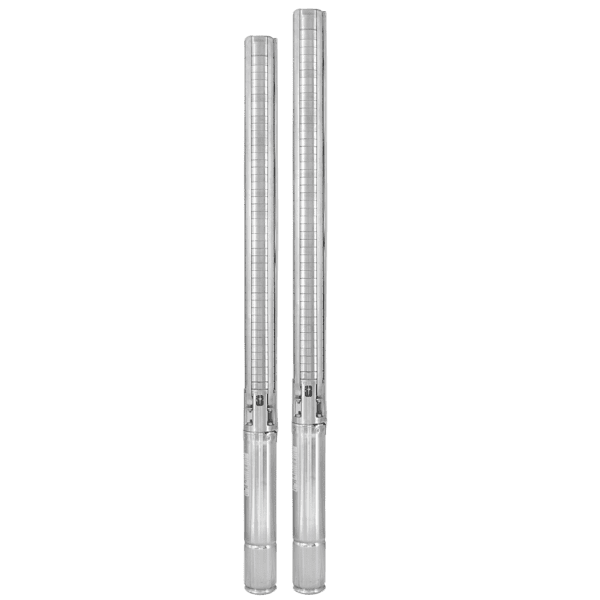

4″ Oil Filled Stainless Steel

Description

- Motors are designed using enamelled copper wire instead of PVC insulated copper wire. Due to this the design is highly efficient reducing power consumption & thereby reducing cost of operation.

- The motors are filled with special food non-toxic dielectric oil, which lubricates the ball bearing and axial thrust bearings. It also offers insulation and thermal properties which increases the reliability & working life of the motor. <

- Outer casing of the motor is constructed completely with Stainless Steel, which reduces corrosion and gives a good overall appearance to the motor.

- The motors are compact and weigh substantially less, which facilitates transportation storage & installation.

- The electric cable of the motor constitutes three-wire removable cable with watertight connector. This facilitates the changing of the cable, if required, without dismantling the motor.

- The motor are permanently split capacitor motors, which do not require the starting capacitor or a starting switch. Due to this the cost of the control box reduces substantially, thereby reducing the cost of installation.

- The motor are designed for a wide voltage range of operation and are suitable for installation in areas experiencing wide voltage fluctuations.

- All rotating components and assemblies are dynamically balanced to ensure long bearing life and vibration free smooth operation.

- The Pumpsets are compact and slim and can be easily installed in narrow wells.

Specifications

| Flow range | up to 18.8 m³/h |

| Head range | up to 547 metres |

| Rating | |

| Rated speed | 2900 rpm |